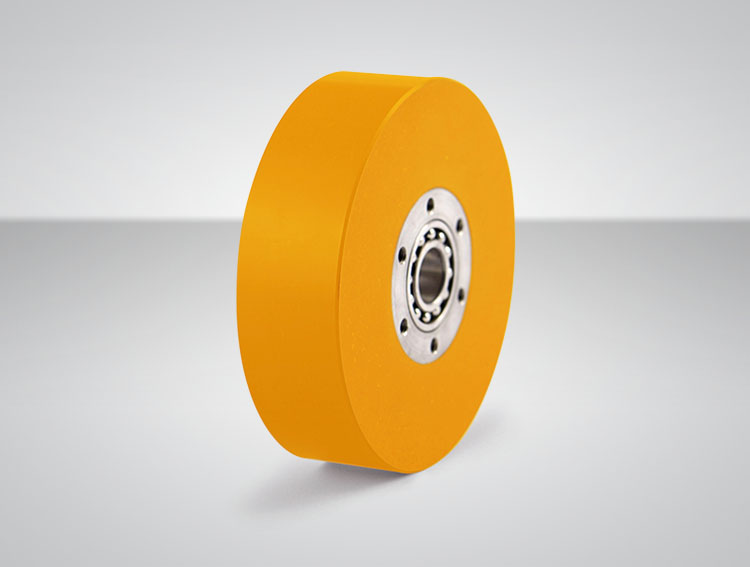

GESADUR® DN

Processing information

Turning

- Use only carbide tools

- K10, clearance angle ~ 5°

- rake angle 0 - 10°

- v = 200 - 250 m / min

- Pre-turn and / or finish turning the parts first

- s Roughing ~ 0.25 - 0.5 mm / revolutions

- s Settle

- Select a 45° angle of adjustment if possible

When turning workpieces on the outside, where the run-out side has already been completely planned, grasp the workpiece with the secondary cutting edge of the turning tool, then finish turning. This prevents the material from breaking off on the run-out side.

Tread Fine Machining

In order to achieve a first-class surface quality, a feed rate of s = 0.03 mm / revolutions should be selected for superfinishing. The best surface quality is achieved by diamond turning.

Drilling

On the pillar drilling machine only with carbide-tipped twist or pointed drills, cutting edge angle ~ 90°, v = 40 m/min, drilling with SS twist drill v = 15 - 20 m / min. When using twist drills, relieve the tension several times.