Manufacturing process

This is how we make vulcanized fibre from wood and cotton

The prepress / base paper

The basic material for the production of vulcanised fibre SAVUTEC® is the renewable raw material cellulose in the form of high-quality special paper. Papers made of cotton linters and / or cellulose are used in particular. The special cellulose fibres required for this purpose come exclusively from certified forest management (FSC / PEFC). These sustainable natural materials are first prepared for further processing in independent procedures. The approx. 3-5 mm long cotton linters fibres used for this are unsuitable for the production of textiles ("non-spinnable short fibres"). They are obtained from the seed hairs of cotton flowers. After harvesting, the cotton linters are mechanically cleaned, boiled and bleached.

The wood, on the other hand, is digested after debarking and crushing, whereby lignin and hemicellulose are dissolved during digestion. The resulting pulp is cleaned and bleached to remove the lignin residues. The white and soft linters and pulp fibres obtained are the raw materials for the high-quality paper, which is produced on specially equipped paper machines. For this purpose, the fibres are dispersed in water and processed into a paper pulp. This pulp, which initially consists of 99% water, flows over an endless screen and is gradually dewatered. The wound up base paper webs are parchmentized at Sachsenröder .

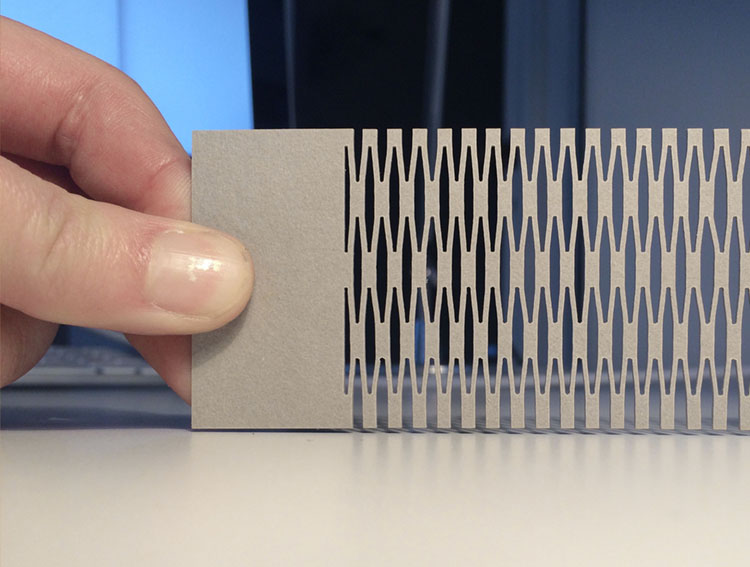

The parchment/vulcanized fibre SAVUTEC®

In parchmentizing, one or more layers of raw paper are drawn through a bath of concentrated sulphuric acid, pressed and then washed out in baths of increasingly low concentration. The acid ensures that the fibres rejoin and a so-called hydrate cellulose is formed. As the sulphuric acid slowly dissolves out, a network is formed which covers all the paper webs lying on top of each other. This process, the so-called ply formation, is equivalent to "welding" the individual paper layers within themselves and also between the individual layers. The sulphuric acid serves as a catalyst, which is completely washed out without leaving any residue (neutral pH value 7). The vulcanized fibre SAVUTEC® is then dried, wound up and packed.