Vulcanized fiber Savutec® SM/SMS

Basis for highest grinding performance

Abrasive vulcanised fibre has high strength after heat treatment; this property plays an important role in resin hardening. Due to high structural strength, high-performance grinding wheels with a lower proportion of vulcanized fibre can be produced. Since our vulcanized fibre has excellent reclimatization properties, a high degree of flexibility is achieved. Vulcanized fibre is environmentally friendly, as it is a pH-neutral cellulose product.

Years of experience and close contact with our customers have led to the development of various types of abrasive vulcanized fibre which cover all areas of application and requirements. Thicknesses between 0.38 and 0.84 mm are available as standard; special thicknesses are available on request.

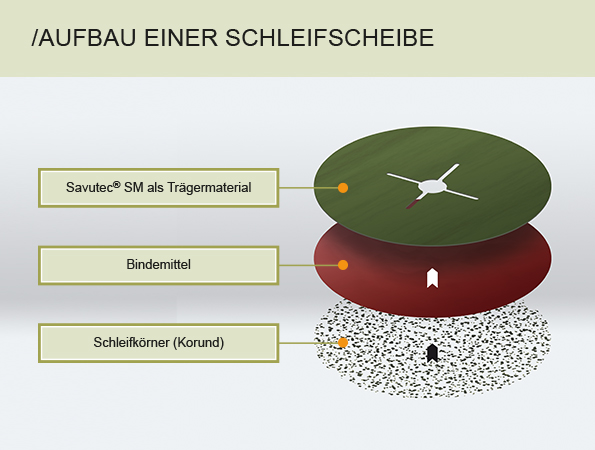

Abrasive vulcanized fibre is the product for the manufacture of flexible grinding wheels - the so-called fibre discs. Flexible grinding wheels of this type are made of vulcanized fibre as backing material, a special binder and the actual abrasive, the so-called corundum grains. Only suitable and high quality of all the above mentioned materials as well as the careful production of experienced abrasive manufacturers guarantee the quality of the flexible grinding wheel.