Natural, renewable and sustainable: vulcanized fiber as a material for high-quality furniture

Increasing ecological awareness among customers versus price pressure: the furniture industry finds itself in a dilemma. Customer demand for sustainable, ecological furniture has never been greater, but producing it is costly and brings further difficulties, for example in terms of design. In this article, we explain why vulcanized fiber is a real game changer in this context as a completely natural plastic alternative based on cellulose.

The new challenges for the furniture industry

As early as 2020, at the IMM Cologne furniture fair, experts in the furniture industry were talking about the Greta effect. The allusion to the well-known Fridays for Future activist was intended to point to a new trend in the furniture industry. Customers increasingly wanted sustainable furniture made of natural and durable materials. The industry responded by bringing more and more ecological products to the market. However, practice today shows that the revolution of the furniture industry does not succeed at the push of a button. As a result, two developments occurred, which we would like to outline for you first.

Good quality for high price

On the one hand, high-quality furniture experienced a boom. The reasoning: The better the quality, the longer the service life of a product. This in turn conserves valuable resources and - since no new furniture has to be built - reduces production-related CO₂ emissions. However, this principle gives rise to another problem. High quality always goes hand in hand with a higher price, so the products are not suitable for the broad customer base.

Mass-produced goods with short service life

On the other hand, as a counter-development, a branch of the market has established itself, which is mainly saturated with inexpensive goods. Visually, this furniture also creates a high-quality, sustainable impression. Often, for example, pressboard is used instead of solid wood to reduce production costs and preserve a natural look. However, the service life of such furniture is low in accordance with the inferior quality - this approach is thus not really sustainable.

Wood - the best ecological choice for the furniture industry?

Regardless of the quality issue, the choice of materials plays a key role for the furniture industry when it comes to sustainability. Natural and renewable raw materials are at first glance the best approach for sustainable furniture. These include not only wood, but also cork, bamboo and sisal. The problem: solid wood, for example, is particularly heavy, cost-intensive to produce, does not permit certain processing methods and must be regularly maintained by the buyer. Many pieces of furniture made of wood are also heavily chemically processed, so that the products are not suitable for composting at the end of their service life. In addition, furniture made of wood has its own characteristic expression, which not everyone likes for their interior. In short, wood and co. as natural and renewable raw materials are a good, but not ideal choice for sustainable, ecological furniture.

Metal and bioplastics - the better material for furniture?

Metal and plastics are also very popular in the furniture industry. Unlike wood, both materials lend themselves to much more extensive processing methods that allow for bold and modern designs. In addition, the service life of metal and high-quality plastics is particularly long, which is positive in terms of sustainability. Now to the problems: Both metal and petroleum - the starting raw material for plastics - are finite. Once the life span of such furniture has been exceeded, further difficulties arise. Recycling is complex, expensive and energy-intensive, which in turn generates further CO₂. Plastics in particular are also often not recycled and remain in the environment, where they degenerate into hazardous microplastics over the years. So-called bioplastics are also not a real alternative here, as they also have to be recycled at great expense and are in no way suitable for composting at home, for example.

Vulcanized fiber as a sustainable material for furniture

Which material combines the key properties of being natural and sustainable on the one hand, and easily machinable and durable on the other? As early as the end of the 19th century, the material vulcanized fiber experienced a boom in this context. The material, which is based on cellulose, was ideal for making fine suitcases and lampshades, for example. The great advantage: vulcanized fiber contains only renewable raw materials and can be processed in a variety of ways. It also has a convincing, high-quality appearance. This is reason enough to take a closer look at the advantages of vulcanized fiber for the furniture industry. But first, let's take a brief look at the manufacturing process.

Natural and renewable

Firm, horn-like and yet easily formable - vulcanized fiber is a real all-rounder, consisting 100 percent of the renewable raw materials cellulose and/ or cotton linters. Both raw materials are parchmentized in a special process with the addition of sulfuric acid. The acid causes the fibers to rebond and form what is known as hydrate cellulose. As the sulfuric acid is slowly dissolved out, a network is formed that covers all the paper webs lying on top of each other. This process, known as ply formation, is equivalent to "welding" the individual paper plies together within themselves and also between the individual plies. To protect the environment, the acid is completely washed out.

Advantages of vulcanized fiber

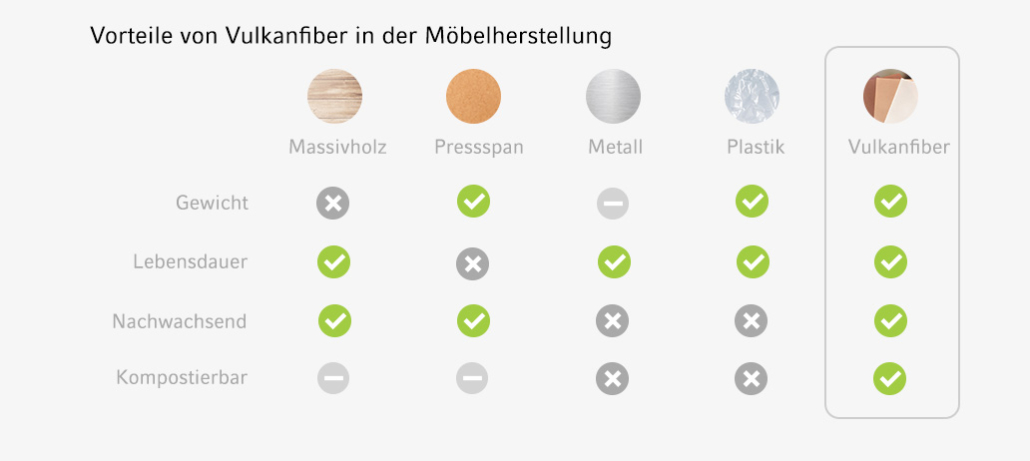

Vulcanized fiber offers a whole range of advantages for the furniture industry. The material is lightweight, yet extremely robust as well as durable and offers a high-quality appearance, where the color can be freely selected. In addition, a large amount of processing methods are available to the furniture industry for diverse designs:

- Compaction

- Deep drawing

- Forming

- Bending, punching, stamping, drilling, filing, milling, etc.

- Coating

- Grinding

Lightweight and suitable for home compost

Due to the enormous resistance with low weight, the vulcanized fiber belongs to the lightweight materials. This is also advantageous for furniture production. Unlike solid wood furniture, for example, an equally robust product can be made from vulcanized fiber with lower material requirements. This reduces production costs without compromising quality. Despite its enormous resistance, the material does not create any recycling or disposal problems, unlike plastic, metal and chemically processed wood. Vulcanized fiber decomposes even in home compost without leaving any residue and thus poses no challenge whatsoever for industrial recycling centers.

Durable and safe

In addition to high mechanical strength, vulcanized fiber convinces with a pronounced resistance to oils, gasoline and other organic solvents. Thus, furniture made of vulcanized fiber is not only durable, but also provides great protection against various liquids in the event of a household accident. In addition, the material is convincing in terms of safety aspects. Vulcanized fiber does not splinter, has a high flash point and - if a fire should nevertheless occur - burns with a small, yellow and even flame.

Develop the sustainable furniture of tomorrow now

Customers' desire for affordable, natural and sustainable furniture in a variety of designs is growing. The furniture industry must rethink now in order not to leave valuable market potential untapped. As a manufacturer of vulcanized fiber SAVUTEC®, we are happy to assist companies in the furniture industry as a development partner for innovative and high-quality furniture. Request a sample now or get in touch with our experts.

For more information and news, feel free to follow us on LinkedIn!

Click on the button below to load the content of LinkedIn.

Contact

Start your inquiry now

Location

Germany

Sachsenröder GmbH & Co. KG

Friedrich-Engels-Allee 143

D-42285 Wuppertal

PO Box 20 16 22

D-42216 Wuppertal

T +49.202.280 54-0

F +49.202.899 93 7

Sales Partner

international

Here you will find information about our international sales partners. Our partners are looking forward to your inquiry!