Vulcanized fibre: From tradition to innovation

It is now well known that global plastic production poses a threat to our environment. Our blog has therefore already taken up the topic of environmental pollution through plastic. A solution to this problem could be a traditional material. May we introduce: Vulcanized fiber, the effective alternative with which the world of tomorrow can manufacture numerous products without using plastic.

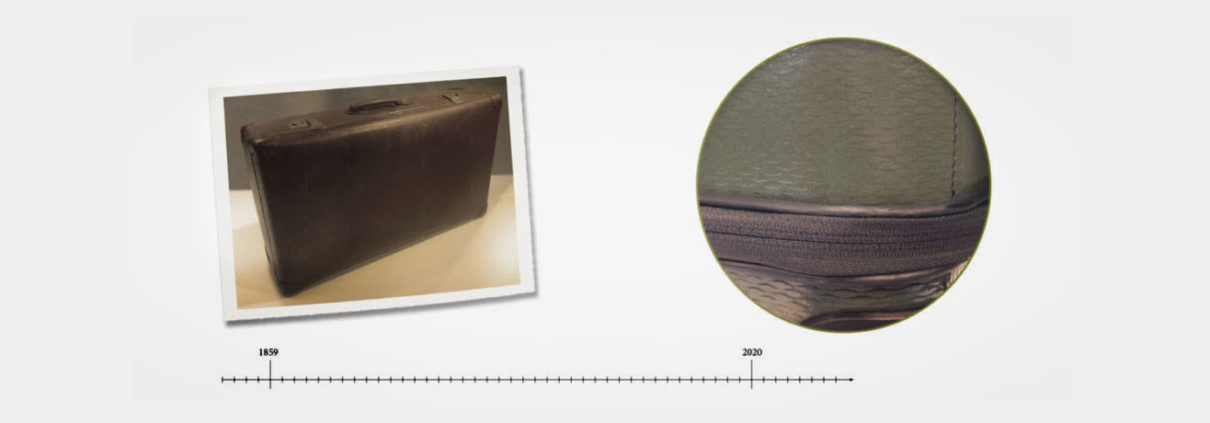

A natural material on the road to success for over 150 years

The vulcanized fibre has been known since 1855 and was first industrially produced in 1859 by Thomas Taylor. The versatile laminate quickly established itself on the market. It was used, for example, to produce suitcases and lampshades. This was made possible by the variable material properties: vulcanized fiber is a hard, tough, non-splintering and hornlike material. It can be bent, embossed, punched, cut, lasered, planed, drilled, milled, coated, printed or glued. However, the most important properties in our time were not even in focus at that time: Vulcanized fiber is based on renewable raw materials (cotton fibers as well as cellulose) and is therefore an ideal substitute for many products and applications based on plastic. In addition, vulcanised fibre can even be degraded in home compost without leaving any residues.

Plastic displaces the vulcanized fibre

In spite of its diverse material properties, vulcanized fiber has meanwhile been forgotten as a material with innovation potential. Among other things, the invention and industrial mass use of plastics contributed to this. According to researchers at the University of California, about 8.3 billion tons of plastic have been produced worldwide since 1950. Today we are feeling the consequences - and vulcanized fiber is now celebrating its comeback. True to the motto: A classic material saves the world of tomorrow.

Vulcanized fibre - a valuable substitute for the future

In contrast to so-called bioplastics, which often do not decompose completely, vulcanised fibre does not leave any residues even in home compost. The material properties of vulcanised fibre also make this traditional plastic substitute a true all-rounder. The material is suitable for numerous industrial applications. From materials for the automotive sector, lightweight construction in the building industry, medical technology and packaging materials to numerous areas of application in mechanical engineering, the most diverse uses are conceivable with vulcanised fibre.

Shaping the industry of tomorrow with vulcanized fibre

What once began with lampshades and suitcases can now shape all branches of industry and help to provide the economy with sustainable and environmentally friendly production for the future. In this respect, by no means all possibilities are exhausted, because: Although vulcanised fibre has been around as a material for more than 150 years, its modern use is still in its infancy and offers far-reaching potential for the future. Now it is up to companies to rethink and use a traditional material as the basis for tomorrow's innovations.