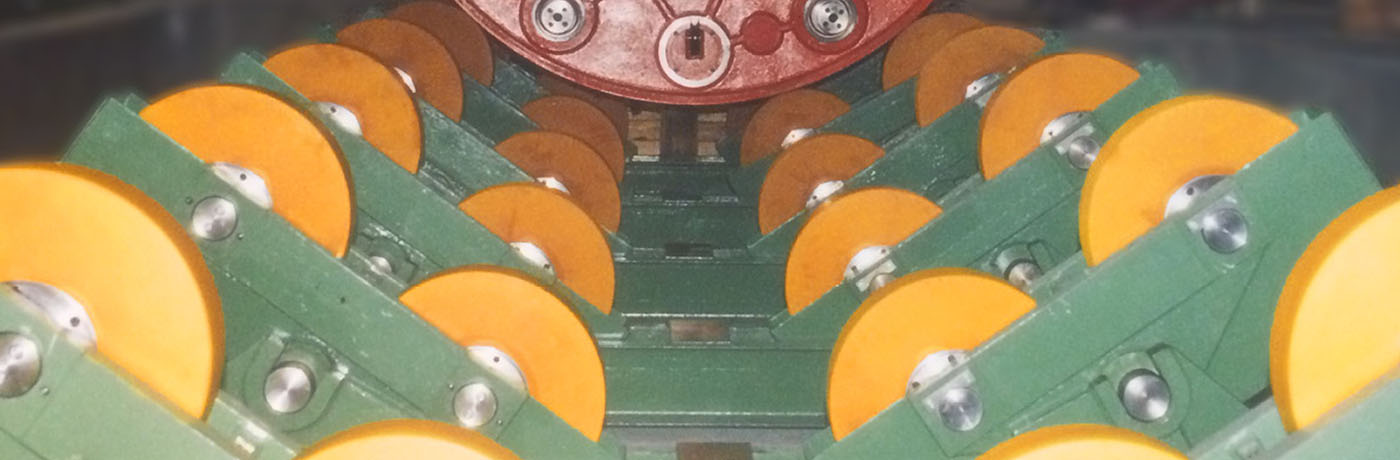

New design of underrollers

The dimensions of the underrollers are calculated according to the Stribeck rolling press curve. Please refer to our separate calculation brochure. When manufacturing underrollers, it is irrelevant in terms of price whether the bore has a small or large internal diameter. We therefore recommend a small bore with a steel bush of a low wall thickness.

The specific gravity of GESADUR® DN is 1.37 g/cm³, as opposed to approx. 7.8 g/cm³ of steel. This saves weight. Cost savings also come from the lower price of a smaller steel bushing. For the steel bushing we recommend normalized steel. Gray cast iron is also used, but this can shrink over time, and then an interference fit is no longer guaranteed.

To achieve the best concentricity accuracy, the following procedure should be followed: The steel bushing is manufactured with an extra length of 20 mm (see diagram 01). After pressing in the steel bushing and pinning it with the 3 clamping sleeves, the roll is clamped at the extra length on the lathe from outside.

Thus, outer and inner diameters can be turned in one clamping. The extra length is turned in a separate operation, the concentricity accuracy is max. 0.01 mm. We recommend turning the outside diameter (the running surface) with a natural diamond, because the best accuracy and running surface is achieved with the natural diamond. Normal carbide tools could wear out during precision machining. The roller would then be slightly conical.

Maintenance and cleaning

Due to dusty working areas, dirt particles can accumulate on the roller surfaces. As a result, the rollers are only loaded and overloaded selectively, so that they can finally burn. For cleaning the tread surfaces we recommend our wheel cleaning device and wheel cleaning agent GESACLEAN.